Free shipping on purchases over 300€ ![]()

99% FILTRATION EFFICIENCY

Portable suction unit with mechanical filtration without fume extraction speed adjustment...ON-OFF only.

AER201 is designed to extract and filter all fumes produced during welding. Supported applications are: MIG/MAG - PULSED MIG/MAG - MMA - TIG

External metal structure, in painted steel, resistant to accidental impacts due to use, light weight and practical carrying handle make it easy to move.

2 metres long flexible hose with a plastic suction nozzle and magnet for secure attachment to metal parts.

Filter section consisting of a metal anti-spark pre-filter, a cartridge filter to be replaced every 500 working hours and an activated carbon filter to be replaced only when bad odours appear.

The portable purifier has been designed for the extraction of fumes generated by non-oily welding processes, in closed or hard-to-reach environments, for short operating times.

AER201 can also exhaust the filtered air outside the workplace, thanks to an optional hose (recommended max. 5 metres).

Original Air service filters are tested and certified according to CEN 779 - EUROVENT 4/4 - CEN EN 1822

Hose diameter : 50 mm

Motor power : 1.1 kW / 230V / 50Hz

Air flow : 250 m3/h

Fume extraction capacity : 110 m3/h

Noise level : 72 dBA

Total weight : 20 kg

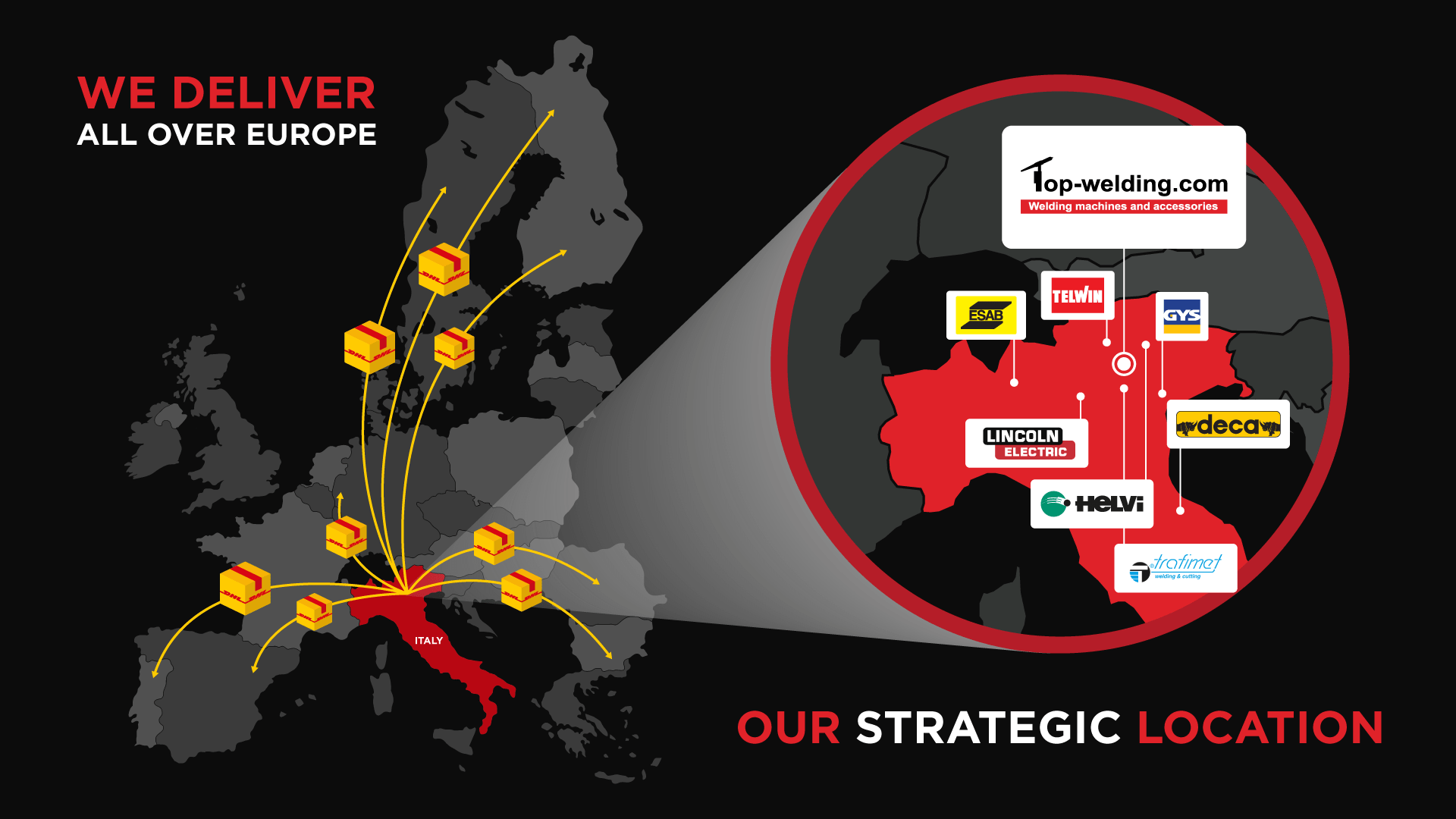

Fast delivery (3-5 days) with DHL Courier in Germany

Free shipping

Choose your country

Choose your country99% FILTRATION EFFICIENCY

AER201 99 air purifier is a single-phase vacuum cleaner that guarantees high operating efficiency while maintaining a low noise level of 72 dBA.

With fume extraction speed adjustment device.

230V/1F/50Hz power supply

1.1kw maximum absorption.

This fume extractor is very compact and the convenient handle at the top, in combination with the low total weight, makes it easy to handle; ideal for use at home or in confined spaces, the painted steel body is solid and resistant to accidental impacts.

Total weight: 22 kg

AER201 99 is equipped with a potentiometer with which the operator can adjust the extraction fume power, up to a maximum of 110 cubic metres/hour, ideal for fumes generated by any MMA, MIG/MAG, PULSED MIG/MAG/TIG welding process.

AER201 99 welding fume extractor is equipped with a 2 metre flexible hose (50mm diameter) with conical suction end.

On the suction nozzle (90 mm diameter) of the AER 201 99 is fixed a magnetic support to ensure optimum anchorage on any ferrous base and maintain the position chosen by the operator.

AER201 99 air purifier is supplied complete with a filter pack (spark-proof metal filter, H13 cartridge filter and activated carbon filter) that guarantees 99% particle filtration.

AER201 can also exhaust the filtered air outside the workplace, thanks to an optional hose (recommended max. 5 metres).

Original Air service filters are tested and certified according to CEN 779 - EUROVENT 4/4 - CEN EN 1822

The portable fume extractor is supplied with:

- Aspirator AER201 99

- 2 metre flexible hose

- Conical nozzle with magnetic holder

- Spark-proof metal filter

- H13 cartridge filter (99% )

- Activated carbon filter

Fast delivery (3-5 days) with DHL Courier in Germany

Free shipping

Choose your country

Choose your countryWhen proceeding with a welding operation, you need to consider various collateral aspects that are not limited solely and exclusively to the choice of a good welding machine or the choice of a specific metal to be welded; it should also be pointed out that it is not enough to consider only the most suitable welding technique in order to obtain a final result of excellent workmanship, nor the consequent choice of the gas, pure or mixed, that will be used. We must bear in mind that the welding process is closely related to a series of chemical reactions that interact together, so we should also pay attention to the precautions to take in order to protect ourselves as much as possible.

According to a survey recently carried out by ISTAT (National Institute of Statistics), it has emerged that about one million people on the national territory work full time in close contact with welding machines. About 30% more people practice welding as a hobby. Unfortunately, many in the latter group do not use suitable precautions to protect their health. It is understandable why the people working in the sector place a great emphasis on the extreme delicacy of the issue of health and the need to control safety at work.

Everyone who uses the welding process on a daily basis for work, or even sporadically as a hobby, tends to use appropriate personal protection devices such as gloves, masks or welding goggles that protect against the sparks and light that welding itself causes. Personal protection is not limited to this, because it must be mentioned that welding releases a series of extremely harmful fumes in the air, composed of gases, vapors of various kinds and particles of lead, manganese, iron and other materials.

Prolonged inhalation of these welding fumes can cause serious and in some cases fatal diseases such as saturnism, a disease caused by accidental exposure to lead; such exposure causes damage to the respiratory and lymphatic system. Other diseases that could result from the inhalation of welding fumes are epilepsy, Parkinson's disease and, in the worst cases, the formation of tumors especially in the respiratory and digestive system.

At this point we can ask ourselves a question: how much smoke is released into the air by the welding process?

Of course, there is no univocal answer, since the emission is the result of everything that contributes to the welding process: first of all, the technique used for the fusion of the metals together, the choice of the metal to be melted or the electrodes that form the welding machine. It is therefore understandable that not only the quantity but also the chemical composition of the fumes themselves is fundamental. Let's not forget that the Italian law has a specific regulation, UNI EN ISO 10882-1, that regulates the sampling of particles and fumes caused by the welding process in the areas immediately circumscribed by the welder.

The picture painted in the last few lines may seem excessively negative, but a machine comes to our rescue, essential for those in this work or even for those who do it as a hobby in the garage of their own home: the welding fume extractor.

The welding fume extractor is a vacuum system that, positioned near the work area, sucks in the fumes created, thus protecting the health of those who are working.

Unless you decide to purchase a portable welding fumes suction system, the purchase and design of such system is not fully classifiable as DIY. Fixed suction systems are precisely designed and conceived by expert companies in the field that, according to the customer's needs, create a perfect plan for extracting the welding fumes, with the insertion in the working environment of pipes for the airflow that, once recycled and purified through the presence of suitable filters, will release in another area of the working environment. And that's not all: in addition to the design and installation of pipes, filters and conduits, these companies will also offer the design and assembly of the mechanical arms that provide the suction and, depending on their length, the perimeter arrangement of the surface where the welding process will happen.

The choice of the welding fume extractor is not so immediate and it is necessary to take into account certain variables and, based on these, you can choose the ideal type of extraction.

The first thing you need to do before purchasing a vacuum system is to prepare the work environment that will accommodate the installation. If the work environment will always be the same you can , opt for a fixed fumes extraction system that will be equipped with a zinc wall pipe system and aerial suction arms that can be easily moved to the area to be vacuumed. They can have a work surface of variable dimensions according to the customer’s needs.

If, on the other hand, the work area is mixed, the best choice will be to purchase a mobile welding fume extractor. It is very compact and equipped with wheels for easy movements and is suitable for occasional work piers with low emission of harmful fumes. It has a very powerful and noisy motor and it is equipped with a mechanical arm that can reach up to three meters in length.

Another very common solution is the installation of a welding booth which is equipped with suction walls and a containment pipe, suitable for the direct suction of welding fumes directly from the work surface. Welding boxes are suitable when the pieces of metal to be welded are particularly large and would not fit into a common working environment.

The piping system becomes a fundamental element as it is designed to maximize the reception of welding dust and fumes as well as to reduce the noise that the system will create.

Depending on these last two factors, the suction power of the system must be chosen. Naturally, the more powerful the system is, the more harmful fumes that will be filtered in the pipes and introduced into the environment as clean air will be eliminated in the near future.

It seems obvious, but the choice of the vacuum system does not depend directly on the type of welding machine used. In short, there are various models of welding machines and each one can be differentiated from the other: the first immediate classification can be made on the basis of the metals that can be welded, the quality of the electrodes, the gas used and the type of filler material supported.

Certainly a factor to be taken into consideration when purchasing a welding fume extractor is the average amount of work that will be carried out on a daily basis or over a more or less short period of time. The type of metals that will be mainly used in the welding process and the size of the processed products should also be evaluated. Then, you must take into account the area in which you intend to work.

On the market, there are various welding fume extractors, each one has a well-defined price range and sometimes, if you are lucky, you can also find offers that lower the basic price to entice users to buy. Given the importance and delicacy of their function, we do not recommend the purchase of used vacuums, since they may have malfunctions due to wear and tear that are difficult to keep under control. In the case of fixed vacuum cleaners or welding booths it is preferable to choose, even if this requires a greater expense, new systems designed and installed by specialized companies. Online you can find several of them and each one offers quite advantageous offers to satisfy its customers.

IN CONCLUSION

Whether you are an experienced welder or a DIY enthusiast, the advice we can give you is not to base the purchase of the welding fume extractor only on the quality of the welding machine, but also to focus attention on other factors that are no less important and from a certain point of view, even more important for health. Remember, as mentioned above, that fumes caused by the welding process are extremely harmful to your health and well-being; in the worst cases, they can also lead to the formation of neoplasms in the respiratory and digestive tract. Therefore, when evaluating the purchase of a suction system, don’t focus your attention and consequently your choice on cheap products; it is better to spend a little more and be totally sure of your safety. If you are a DIYer and your workload is small, naturally try to choose a mobile suction system with wheels to ensure maximum ease of movement from one area to another. If, on the other hand, you have a specialized workshop and a greater workload, of course you can only turn to the various companies that deal with the design and implementation of the entire vacuum system and related air recycling. In addition to what has been recommended so far, it is also advisable to consider the purchase of PPE (personal protective equipment) such as gloves and apron in fireproof material, masks or goggles.

Finally, keep in mind that all the vacuum systems do not solve the problem one hundred percent and therefore, to complete the work, it is essential to have a working environment where there is a good ventilation system, with windows or doors around it to allow an optimal airflow of the air you breathe.

Happy welding to you all