Free shipping on purchases over 300€ ![]()

Online support / Phone

Email : info@top-welding.com

Choose your country

Germany

Germany

| Code | 816145 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Cutting Current | 10 - 40 A |

| Cutting Thickness | 15mm steel separation |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Germany

Fast delivery (3-5 days) with DHL Courier in Germany

| Code | 816146 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Cutting Current | 10 - 40 A |

| Cutting Thickness | 15 steel separation |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Germany

Fast delivery (3-5 days) with DHL Courier in Germany

| Code | 0559160135 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Cutting Current | 5 - 35 A |

| Cutting Thickness | 12mm steel, 10mm stainless steel, 8mm aluminium |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Germany

Fast delivery (3-5 days) with DHL Courier in Germany

| Code | 029743 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Cutting Current | 10 - 40 A |

| Cutting Thickness | 15 mm acciaio - 10 mm alluminio |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Germany

Fast delivery (3-5 days) with DHL Courier in Germany

| Code | 0559160145 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Cutting Thickness | 16mm steel, 12mm stainless steel, 10mm aluminium |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Germany

Fast delivery (3-5 days) with DHL Courier in Germany

| Code | 816148 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Cutting Current | 10 - 60 |

| Cutting Thickness | 20 steel separation |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Germany

Fast delivery (3-5 days) with DHL Courier in Germany

| Code | 816147 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Cutting Current | 10 - 40 A |

| Cutting Thickness | 12mm steel separation |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Germany

Fast delivery (3-5 days) with DHL Courier in Germany

| Code | 0559130004 |

|---|---|

| Power Supply (V) | 120-240 V AC +/-10%, 50/60 Hz 1 Ph |

| Cutting Current | 10-30 A |

| Cutting Thickness | separation 16mm, clear cut 10mm |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Germany

Fast delivery (3-5 days) with DHL Courier in Germany

| Code | 0559150004 |

|---|---|

| Power Supply (V) | 50-60 Hz 3 Ph x 400V |

| Cutting Current | 15 – 50 A |

| Cutting Thickness | separation 32mm, clear cut 16mm |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Germany

Fast delivery (3-5 days) with DHL Courier in Germany

| Code | 816170 |

|---|---|

| Power Supply (V) | 50-60 Hz 3 Ph x 400V |

| Cutting Current | 20 - 50A / 20 - 70A |

| Cutting Thickness | 30 Steel separation |

| Access to the data sheet | |

| Accessories | |

In the welding world, it is essential for the operator to have all the tools he needs to perform any job easily and safely. People often underestimate the enormous difference a single device can make. One of the most fundamental and widely used tools in carpentry is the inverter arc welding machine, which is designed to permanently join two pieces of metal material in a single joint through the welding process.

When working with metal parts, it is also useful to have a tool that can cut/separate steel plates so they can be processed. Until a few years ago, the most widely used tool was the oxyacetylene flame, which had several disadvantages: first of all, it is dangerous due to the use of acetylene gas, but other disadvantages were the high price of the cylinder and gas refill and the strict safety regulations.

Another obstacle for the use of the oxyacetylene flame is the difficult handling in the workplace due to the weight and size of the gas cylinders. An inexperienced operator may find it difficult to handle the gas in the torch, or he could make an incorrect adjustment of the tip, making a lower quality cut.

In recent years, especially in the industrial sector, but also in the private sector, oxy-acetylene flame cutting has been replaced by the most recent technology of plasma cutting.

This technology can cut or separate in an easy, fast and safe way thick metal plates, even over 40 mm thick plates, with a manual procedure. The cutting capacity of the plasma cutter depends on the inverter model and on the torch used in the processing.

As mentioned above, plasma cutting has several advantages over classic oxyacetylene flame cutting: first of all, the absence of gas is a very important factor both from a practical and economic point of view.

The risk of gas leakage and the use of open flames by operators is reduced to zero. The storage of acetylene gas cylinders is strictly regulated, and the gas is not always easily available at a reasonable price.

In the last 20 years, with the appearance and improvement of inverter technology, plasma cutters have been reduced in size, making them compact and suitable for transport to the worksite or processing location. With a plasma cutting generator you can cut any ferrous material that conducts electricity without the need to invest more money in another cutting system.

HOW DOES A PLASMA CUTTER WORK?

A plasma cutting machine needs two fundamental elements to function, air and electricity.

The machine transforms air into plasma, which is an overexcited state of matter, but how is this possible?

The mass, the positive terminal of the plasma cutting machine, is connected to the base metal, charging the entire surface of the metal with positive current. Inside the torch of the plasma cutter in a small channel there is a negative electrode and the surface of the channel where the compressed air flow is positive. This difference in polarity generates a small electric arc.

The compressed air in contact with the electric arc completely changes its constitution. Now the air is no longer a gas, but a mixture of positive ions and free electrons, called plasma. When the torch is placed on the base metal (positive), all the ions and electrons are attracted with great force and ignite the "flame" that easily cuts the metal. Compressed air moves and cools the molten metal and keeps the flame of the plasma cutter going.

TYPES OF PLASMA CUTTERS

There are two main types of plasma cutter. They are divided according to the presence or absence of the compressor.

The compressor can be incorporated into the plasma cutter or connected externally, the main difference is that a plasma cutter with an internal compressor is easier to handle and to bring with you, compared to an inverter plasma cutter generator that needs the external compressor.

Another key element to consider before buying a plasma cutter is the cutting capacity of a given machine.

Clean cut capacity and metal separation are two very different things: clean cut capacity refers to the thickness that a plasma cutter can cut with great precision leaving the edges of the material perfect, which is a high-quality cut.

Metal separation, on the other hand, refers to the ability of a plasma cutter to effectively separate a metal at a fixed thickness without paying attention to the aesthetics of the cut itself.

It is recommended to get a plasma cutter with a cutting capacity of at least 20%, 30% more than the thicknesses that you usually want to cut. By doing so, in addition to obtaining a clean cut, you will not have problems with overheating the plasma cutter. This "rule" mainly applies for operator that have to make cuts continuously.

A further subdivision is the ignition mode. The cutting arc can be ignited in high frequency (HF) and the generator can ignite the cutting arc without making the torch touch the metal. The traditional method is contact igniting, where the operator puts the torch tip directly on the piece that he wants to cut. This last method of ignition is generally used in automatic cutting machines.

Please note that even plasma cutting generators have a fixed work cycle, which determines the generator's operation in minutes at a given amperage.

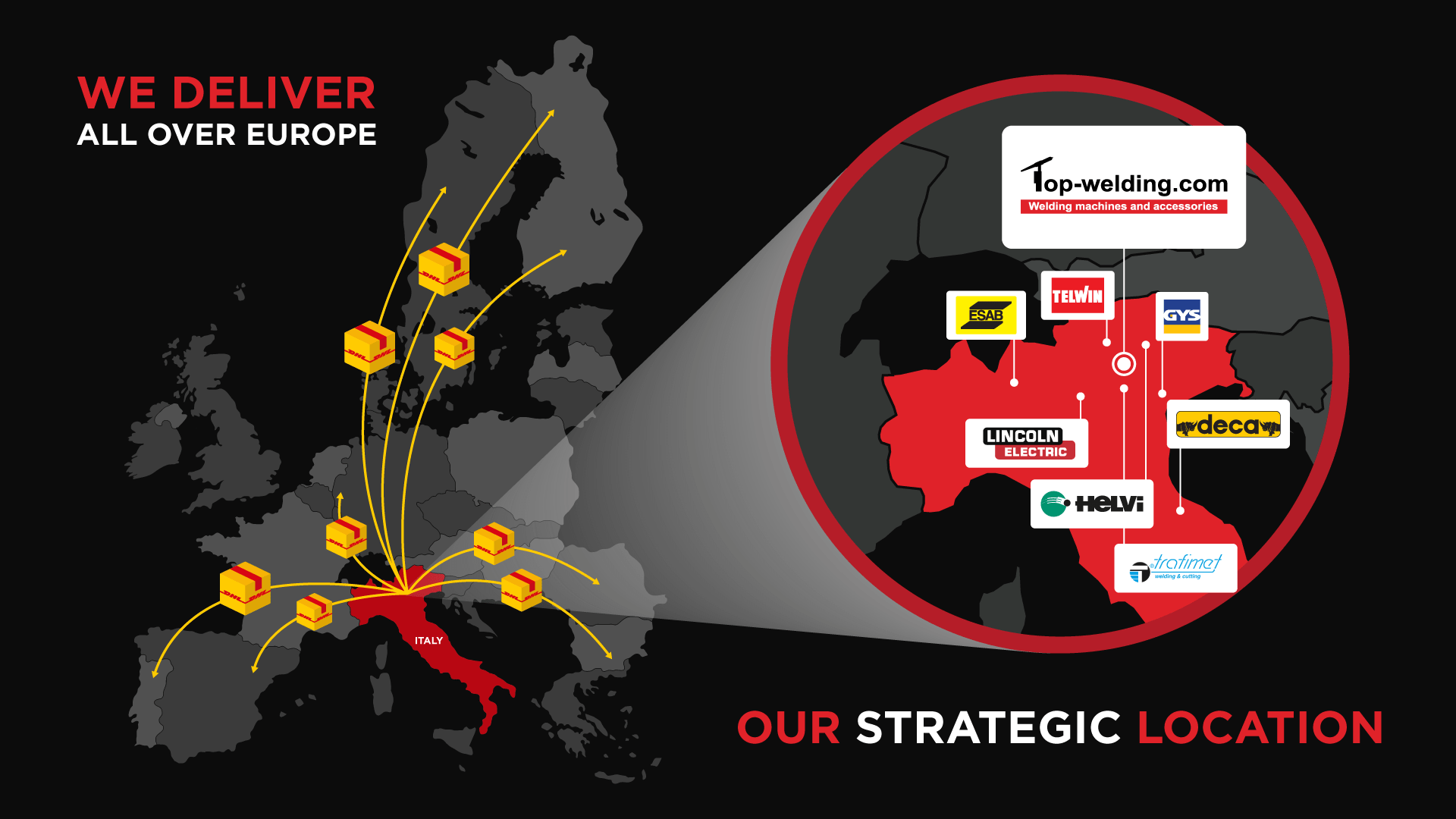

Top-Welding has a selection of plasma cutters of the best brands, Telwin, Gys, Helvi, Lincoln... which guarantee reliability and quality.

Among the most requested models there are:

- Telwin Technology Plasma 41 XT

- Telwin Infinity Plasma 40

- Telwin Technology Plasma 54k XT

- Gys Easycut 40

- Esab HandyPlasma 35i

- Lincoln Tomahawk 1025

If you are looking for a plasma cutting system that is not listed in our product list, please contact us for a custom quote.