Free shipping on purchases over 300€ ![]()

| Combinations | Price | |

| 14,45 € | ||

| 12,48 € | ||

| 13,44 € | ||

Flux cored wire coil Ø 100mm 700 gr. Available in three different thickness :0.8, 0.9 e 1.2 mm.

Weight 700 gr

This wire doesn't need gas

Fast delivery (3-5 days) with DHL Courier in Germany

Choose your country

Choose your country| Combinations | Price | |

| 36,69 € | ||

| 32,54 € | ||

| 34,20 € | ||

Flux wire coil 2 Kg.

3 available thickness 0.8 - 0.9 and 1.2 mm

1.2mm diameter is 2.5 kg

No gas need

For steel welding

Fast delivery (3-5 days) with DHL Courier in Germany

Choose your country

Choose your countryFlux-cored wire coil 4.5 Kg

Wire diameter 0.9mm

Use without gas

For iron welding

AWS A 5.20: E71T-GS

DC-

Fast delivery (3-5 days) with DHL Courier in Germany

Choose your country

Choose your countryArc welding of mild steel, stainless steel and aluminum using the MIG MAG wire process is historically designed for industrial use, but in recent years it has been increasingly used in the domestic sector, partly due to the appearance of a wide variety of accessories and models of multi-process inverter welding machines, increasingly popular among hobbyists for the various features they offer and the wide range of millimeters they allow to weld.

Advantages of wire welding

Continuous arc welding with MIG MAG wire is widely used at the industrial level because it offers many advantages.

The most appreciated are the quality of the weld bead, which is aesthetically appealing, and the high working speed that this welding process offers without the need to interrupt the work process to reequip the welding machine, unlike the MMA process.

MIG continuous wire welding uses a shielding gas that flows out of the welding torch when you use it, covering the weld pool, preventing oxidation of the weld bead. The amount of power used during welding may change based on the amount of liters/minute of gas supplied.

Mig welding requires at least one gas tank connected to the welding machine and a working environment sheltered from the wind, since this could make the flow of the gas protecting the wire useless, resulting in a partially or completely oxidized bead.

Even though the price of flux-cored steel wire is higher, this wire is used more frequently for hobby applications compared to solid wire. With the use of a few inexpensive accessories (anti-stick spray, solder paste), you can obtain good-quality soldering without having to purchase the protective gas cylinder.

The no-gas flux-cored wire can be used without any problems in the open air or for outdoor work, compared to the use of the coated electrode.

The no-gas flux-cored wire works on the same principle as the coated electrode used in MMA welding, but with the advantage of not having to interrupt the process to replace the electrode.

Inside the no-gas flux-cored steel wire there is a mix of minerals that burns during the melting process, creating a gaseous atmosphere that isolates the weld pool and releases a deposit that protects the weld bead from oxygen while it cools down, known as "slag".

To use the flux-cored no-gas wire, it is recommended to equip the welding machine with a wire roller that can be used with the flux-cored no-gas steel wire, reverse the polarity of the ground cable and of the MIG torch, and obtain a can of anti-stick spray, a small hammer, and a brush with metal bristles to remove the slag from the weld bead at the end of the process, so you can continue with the next welding.

The no-gas flux-cored steel wire can be used on plates thicker than 1.5 mm. The FLUX welding process develops a higher temperature than MIG welding with gas shielding at the same amp. If the temperature is too high, the molten zone can pierce the base material just like what happens with MMA-coated electrode welding.

No-gas flux-cored wire cannot be used to weld stainless steel and aluminum, only mild steel.

During the flux soldering process, there are molten material splashes and slag that can affect the base material. It is therefore recommended to use some anti-stick spray or, alternatively, use protective cloths before working on the material to avoid this problem, which would affect the process.

You can find several models of no-gas flux-cored wire coils on the market, which differ in wire diameter from 0.8 millimeters to 1.2 millimeters and 100, 200, 300 millimeters coil size. It is therefore possible to purchase a of flux-cored wire coil for any welding machine, but it can only be used with the models that allow you to change the polarity between ground cable and the torch.

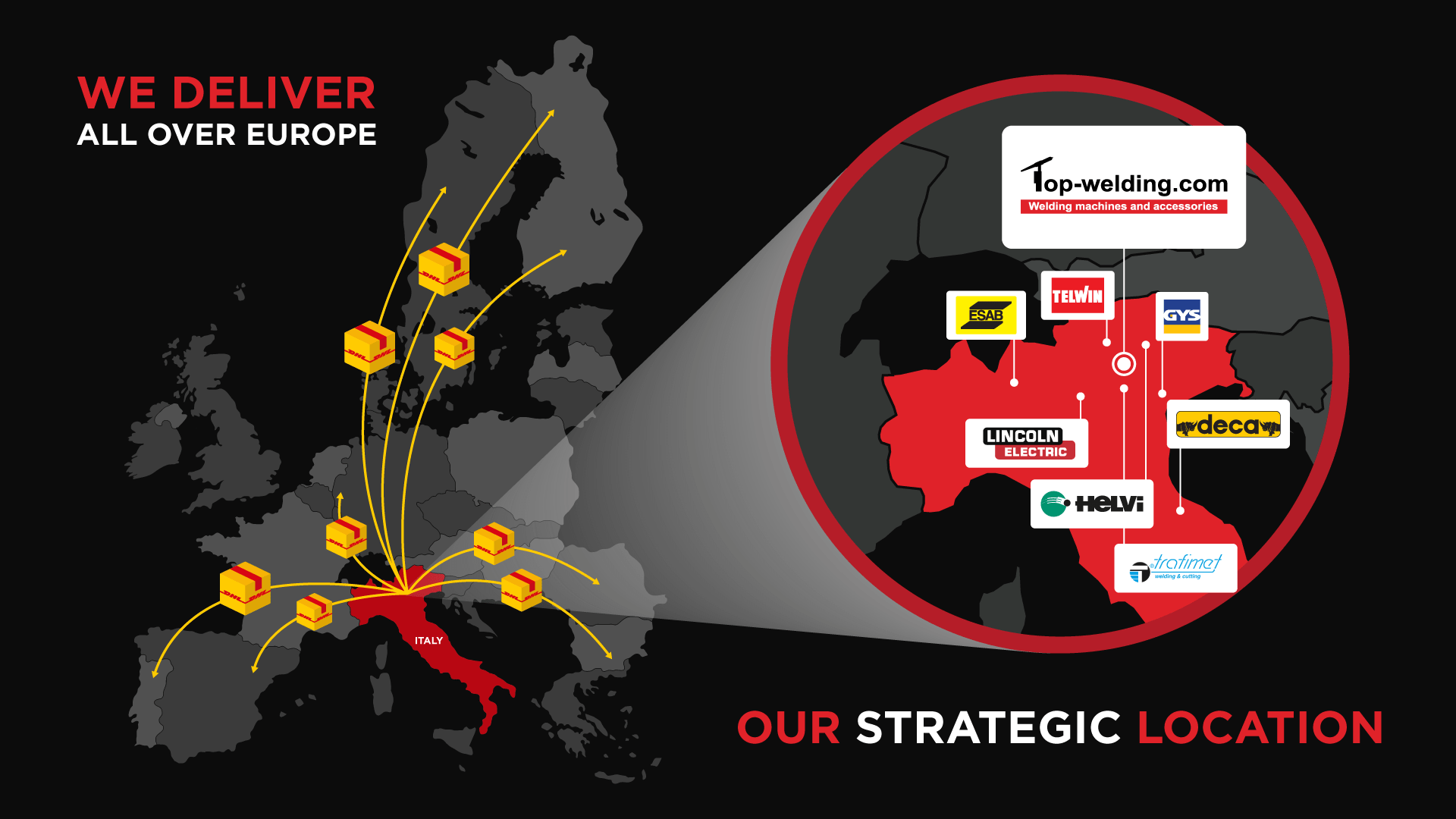

Welding machine and welding equipment manufacturers such as Deca, Telwin, Lincoln, Helvi, Esab and Gys have now integrated this function in all the best multi-process models with synergic and non-synergic adjustment.

In our price list there are several flux-cored wire coils available for immediate delivery, with free shipping (see minimum order). If you need a large quantity of coils or a particular product, please contact us for a custom quote.