Free shipping on purchases over 300€ ![]()

Online support / Phone

Email : info@top-welding.com

Choose your country

Lithuania

Lithuania

| Code | 99820060 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Fuse (A) | 16 A |

| MIG Regulation Field | 10-150 |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 241800 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Fuse (A) | 16 A |

| MMA Regulation Field | 10 - 130 |

| MIG Regulation Field | 10 - 150 |

| TIG Regulation Field | 10 - 150 |

| Supplied with | Torch 110A, cable and mass clamp, gas tube |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 241900 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Fuse (A) | 16 A |

| MMA Regulation Field | 10 - 150 |

| MIG Regulation Field | 10 - 180 |

| TIG Regulation Field | 10 - 180 |

| Supplied with | 3m mig torch, cable and mass clamp, gas pipe |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 816087 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Fuse (A) | 16 A |

| MIG Regulation Field | 20 - 170A |

| Supplied with | Mass clamp + torch connection Euro 150A 3 M |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 816075 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Fuse (A) | 16 A |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 99820052 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Fuse (A) | 16 A |

| MMA Regulation Field | 20 - 180 A |

| MIG Regulation Field | 25 - 180 A |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 242000 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Fuse (A) | 20 A |

| MMA Regulation Field | 10 - 160 A |

| MIG Regulation Field | 10 - 200 |

| TIG Regulation Field | 10 - 200 A |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | B18264-1 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Fuse (A) | 16 A |

| MIG Regulation Field | 30 - 200A |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 816231 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Fuse (A) | 16 A |

| MIG Regulation Field | 20 - 200 A |

| TIG Regulation Field | 20-200 A |

| Supplied with | Torcia MIG-MAG, e pinza di massa |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 248600 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Fuse (A) | 25 |

| MMA Regulation Field | 10 - 160 A |

| MIG Regulation Field | 10 - 200 |

| TIG Regulation Field | 10 - 200 |

| Supplied with | Mass Clamp + torch connection Euro 180A 3 M |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 99820039 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Fuse (A) | 16 A |

| MMA Regulation Field | 20 - 170 A |

| MIG Regulation Field | 25 - 170 A |

| TIG Regulation Field | 5 - 170 A |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 816232 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Fuse (A) | 16 A |

| MMA Regulation Field | 20 - 220 A |

| MIG Regulation Field | 20 - 220 A |

| TIG Regulation Field | 20-220 A |

| Supplied with | MIG torch and a mass clamp (3m) |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 0700301091 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Fuse (A) | 16 A |

| MMA Regulation Field | 30 – 180 A |

| MIG Regulation Field | 30 – 180 A |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 99820053 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| MIG Regulation Field | 20 - 200 |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 816057 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| MIG Regulation Field | 20 - 220A |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 816056 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| MIG Regulation Field | 20 - 250A |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 0700301092 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Fuse (A) | 16 A |

| MMA Regulation Field | 30 – 210 A |

| MIG Regulation Field | 30 – 210 A |

| Access to the data sheet | |

| Accessories | |

Available from 28-05

* Order managed in 24h![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 065093 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Fuse (A) | 13 |

| MMA Regulation Field | 10 - 200 A |

| MIG Regulation Field | 20 - 200 A |

| TIG Regulation Field | 10 - 200 A |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | K14099-1 |

|---|---|

| Power Supply (V) | 115-230V 1Ph 50-60Hz |

| Fuse (A) | 16 A |

| MIG Regulation Field | 20 - 200 A |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 065109 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Fuse (A) | 13 |

| MMA Regulation Field | 10 - 200 A |

| MIG Regulation Field | 20 - 200 A |

| TIG Regulation Field | 10 - 200 A |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 816076 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| MMA Regulation Field | 20 - 220 |

| MIG Regulation Field | 20 - 220 |

| TIG Regulation Field | 20 - 220 |

| Supplied with | MB25 3m torch + 3m cable and mass clamp |

| Access to the data sheet | |

| Accessories | |

| Code | 816196 |

|---|---|

| Power Supply (V) | 50-60 Hz 3 Ph x 400V |

| MIG Regulation Field | 20 - 250 |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 99820035k |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| MIG Regulation Field | 20 - 200 |

| TIG Regulation Field | 5 - 200 |

| Access to the data sheet | |

| Accessories | |

| Code | K14146-1 |

|---|---|

| Power Supply (V) | 115/230V 1Ph 50-60Hz |

| Fuse (A) | 16 A |

| MIG Regulation Field | 20 - 200A |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 0700300985 |

|---|---|

| Power Supply (V) | 115/230V 50/60 Hz |

| MMA Regulation Field | 5 - 240A |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 816065 |

|---|---|

| Power Supply (V) | 50-60 Hz 3 Ph x 400V |

| MIG Regulation Field | 20 - 300 A |

| Access to the data sheet | |

| Accessories | |

| Code | 075030 |

|---|---|

| Power Supply (V) | 50-60 Hz 3 Ph x 400V |

| Fuse (A) | 16 A |

| MIG Regulation Field | 15-320A |

| Access to the data sheet | |

| Accessories | |

| Code | 816903 |

|---|---|

| Power Supply (V) | 50-60 Hz 3 Ph x 400V |

| MIG Regulation Field | 20 - 270A |

| Access to the data sheet | |

| Accessories | |

| Code | 816197 |

|---|---|

| Power Supply (V) | 50-60 Hz 3 Ph x 400V |

| MIG Regulation Field | 20 - 400 |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 0448350992 |

|---|---|

| Power Supply (V) | 50-60 Hz 3 Ph x 400V |

| MMA Regulation Field | 20 A / 20,8 V - 320 A / 32,8 V |

| MIG Regulation Field | 30 A / 15,5 V - 350 A / 31,5 V |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 0700300998 |

|---|---|

| Power Supply (V) | 120/230 monofase +/- 10%, 50/60 Hz |

| MIG Regulation Field | 235A max |

| Access to the data sheet | |

| Accessories | |

![]() Free shipping

Free shipping

![]() Fast delivery (3-5 days) with DHL Courier in Lithuania

Fast delivery (3-5 days) with DHL Courier in Lithuania

| Code | 061835 |

|---|---|

| Power Supply (V) | 50-60 Hz 1 Ph x 230 |

| Fuse (A) | 16 A |

| MMA Regulation Field | 15 - 220 |

| MIG Regulation Field | 15 - 220 |

| TIG Regulation Field | 15 - 220 |

| Access to the data sheet | |

| Accessories | |

CONTINUOUS WIRE WELDING WITH OR WITHOUT GAS

Continuous wire welding can also be performed without the use of shielding gas by using a flux-cored wire (NO GAS or FLUX). The "gaseous" protection is replaced by the wire core. This type of wire welding machine is mainly used outdoors in windy conditions, or for DIY use.

However, welding with the flux-cored wire is not very aesthetically pleasing and does not allow welding of thicknesses below 1.2mm; at the end of the welding process the slag must be removed from the bead. The aesthetic aspect can be considered very similar to MMA electrode welding, with the important advantage that the flux-cored wire process is much faster and more immediate.

WIRE WELDING MACHINE: THE GENERATOR

The mig welding machine is a device whose task is to feed the welding zone with filler material, using a welding torch, and to generate the electric arc that forms between the joint connected to the ground and the torch. The two main adjustments are the wire feed speed and the welding current.

MIG WELDING: GASES

The shielding gases used in MIG welding essentially fall into two categories: inert and active. The first category includes argon and argon-helium mixtures used in MIG welding with aluminum wire or braze welding, while active gases such as carbon dioxide and its mixtures are used for working on iron and stainless steel.

TYPES OF MIG MAG WELDING

In wire welding machines, welding can take place in several ways:

1. Short arc: the filler metal is transferred into the melting bath in the form of droplets by continuous short-circuits.

2. spray arc: thanks to the high current, the wire melts before it touches the base metal and is sprayed into the bath itself, creating a continuous flow of material.

3. pulsed arc: this particular function is present only in certain professional continuous wire welding machines. The pulsations cause small droplets to come off, giving an excellent aesthetic finish to the weld.

MIG WELDING MACHINE FUNCTIONING

The mig welding machine is used mainly in the industrial sector, but it is also increasingly requested for the do-it-yourself sector. The continuous wire welding machine uses a coil of wire pushed by the roller unit inside the torch until it reaches the piece of metal. The wire closes the electrical circuit with the ground clamp, bursting and releases material in the form of drops of molten material, generating the welding bath.

Gas welding can be considered finished and aesthetically pleasing, and generally does not require any further finishing operations. The continuous wire welding machine with gas protection allows very thin thicknesses to be welded and has a high production capacity.

Gas-free flux-cored wire welding uses a special wire that, during fusion, protects the weld pool from external oxidizing agents, and can only be used to weld mild steel (iron). However, it is not possible to weld materials with a thickness of less than 1.2 mm, and the bead must be brushed and cleaned to eliminate deposited slag.

When purchasing an inverter continuous wire welding machine, it is important to check that it is set up for welding with or without gas; it is essential that the polarity change is available inside the coil holder compartment or on the front of the mig welding machine. In continuous flux-cored wire welding, the torch is connected to the negative pole.

High range MIG MAG welding machine

Top-welding.com also offers models of continuous wire welding machines with integrated PFC device that allows welding at high current, even in a domestic environment where 3.5 kw are available. It also makes it possible to power the mig welding machine with the use of long extension cords, of up to 100 meters, or to power it with a motor-generator, which often does not guarantee a constant and stable power supply. In addition, the PFC device guarantees considerable power savings compared to traditional wire welding machines.

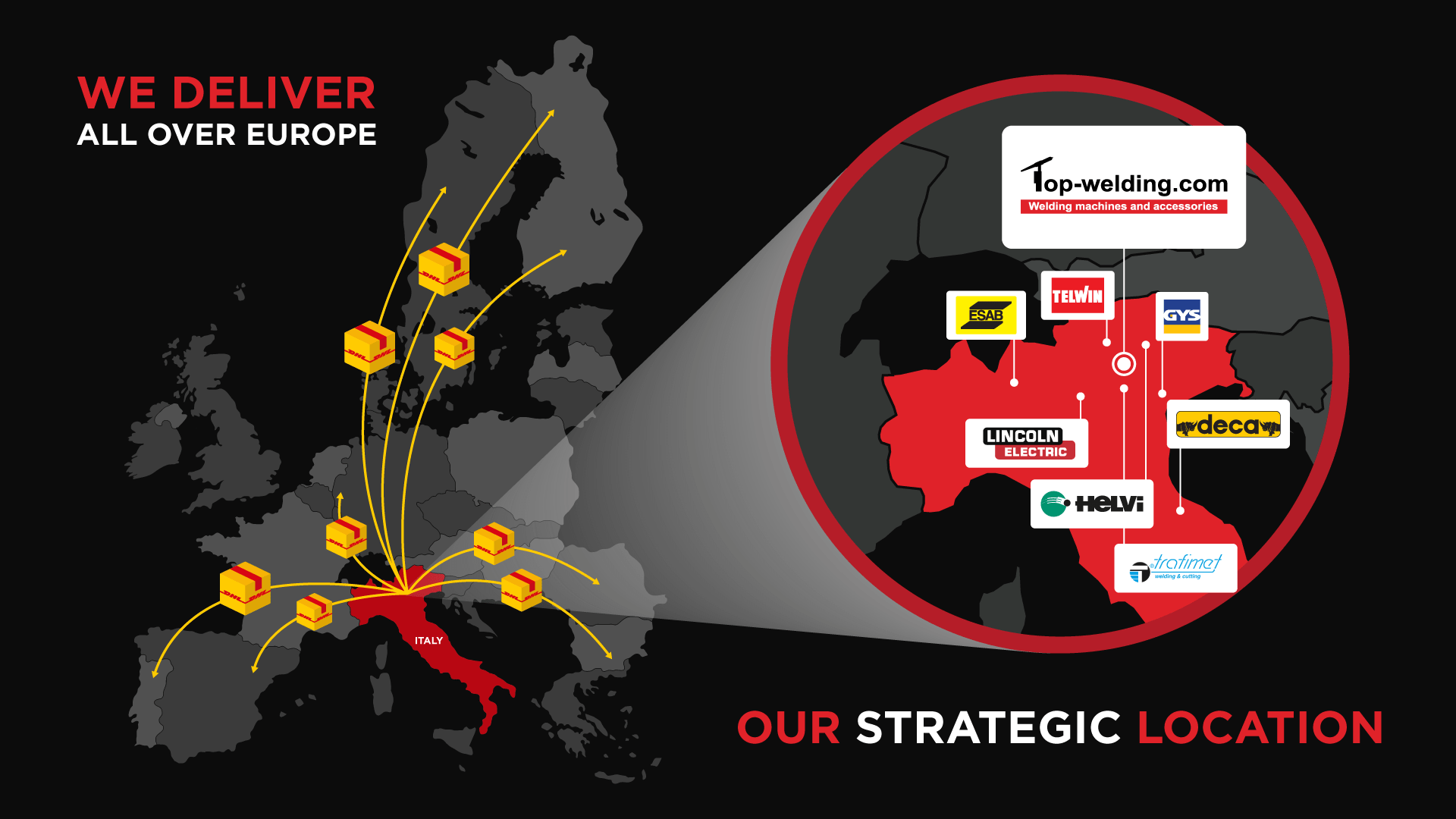

Top-welding.com provides different models of wire welding machines both for DIY and professional use.

- Lincoln Speedtec 200c

- Gys Multipearl 210-4 xl

- Telwin Technomig 215 synergic

- Deca Miga 218

- Esab Rebel Emp 215ic

- Helvi Fox 185

Shipping is free and after-sales service is provided by a helpful and professional team.